JSC Ural Steel

Ural Steel is the optimal combination of rich experience, new technologies, team of professionals and aspiration for leadership.

ALLOY OF THE BEST

We aim to be a leader in steelmaking

-

0+

professionals

at the plant -

0+

km2 Plant

area -

₽0+

bn of revenue

in 2024. -

0+

Russian

consumers -

0+

foreign

consumers

-

View

ViewSinter Plant

The beginning of the production cycle of the plant, where ore is processed and raw material – sinter, necessary for the production of cast iron is produced; sinter is considered to be the main “food” and a kind of “bread” for Blast Furnaces. Automatic dosing of all sintering mix components was implemented here; the fluxed sinter production technology was mastered, which increased output of Blast Furnaces and cast iron quality with a decrease in its cost price.

Read more -

View

ViewCoke And By-Product Production

The largest process of the plant, where coke, the main fuel for pig iron production, is sintered from coal charge. Coal concentrate is crushed and mixed in necessary proportions into coal charge, which is heated above 1000°C without access to air in chamber furnaces combined into coke batteries. Ready coke is cooled by dry or wet quenching and transferred to sorting, where coke, nut and fines are separated. In the process of recovery, coal tar, ammonium sulfate and benzene are extracted from coke gas.

Read more -

View

ViewBlast Furnace Plant

Hot metal with low sulphur and impurities content is cast. Burden loaded into Blast Furnaces is subjected to physical and chemical processes. Iron oxide is reduced forming iron–carbon alloy - cast iron. Hot metal is sent to the Steelmaking Plant or to Casing Machines where it is cast into pigs for export. Ural Steel is one of the largest manufacturers of merchant pig iron.

Read more -

View

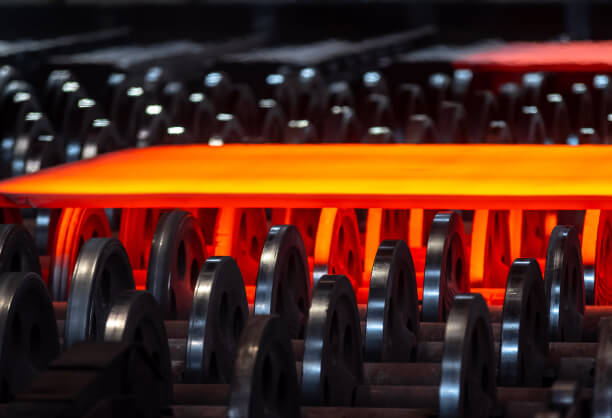

ViewSteelmaking Plant

It is one of the most advanced sites of the Plant. It produces around one hundred steel grades of higher quality. Rounds for manufacture of railway wheels and square billets for manufacture of rails, as well as slabs for further rolling are produced here. The plant successfully incorporated FMF-technology which allows to melt steel using different steelmaking practices not only electric arc melting (with electricity), but also basic oxygen process (without electrodes)

Read more -

View

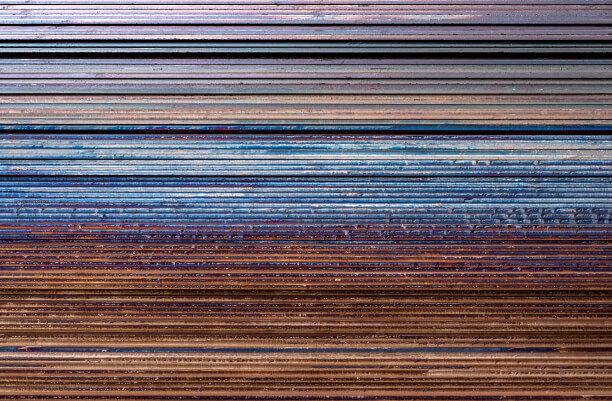

ViewPlate Rolling Mill

In the Plate Rolling Mill, advanced equipment uses slabs coming from the Steelmaking Plant to make rolled products complying with the high consumer properties. Mill 2800 produces up to 1 million tons per year of high-quality steel for bridge construction and shipbuilding, making welded pipes of large diameter and steel structures. Availability of heat treatment and pickling complex allows producing unique corrosion resistant rolled steel products.

Read more -

View

ViewFoundry Plant

It is a unique production of small and large size castings for own steelmaking and blast furnace production needs and also for third-party mining and metallurgical enterprises. Depending on the customer needs, products with the required chemical and mechanical properties, configurations and dimensions, even weighing up to 100 tons will be produced.

Read more

PROJECTS AND SOLUTIONS

Made

of our

steel

-

BRIDGE STEEL

“Red Dragon” bridge over the Irtysh river

More than 100 bridges are built using Ural Steel metal

Products

-

STRUCTURAL STEEL

Moscow International Business Center

Structures of dozens of buildings and stadiums are built using Novotroitsk steel

Products

-

STRIP STEEL

GAS PIPELINE “SAKHALIN-KHABAROVSK-VLADIVOSTOK”

In kilometers of strategic oil and gas pipelines

Products

-

SHIPBUILDING STEEL

Multi-purpose icebreakers

Ural Steel rolled products are in demand among leading shipbuilding companies

Products

-

HIGH STRENGTH STEEL

High strength weldable steel grade "WeldUS 690" and high strength wear-resistant steel grade "HardUS 400"

Ural Steel develops new premium steel grades

PRODUCTS