Production

Ural Steel is an integrated iron and steel works. It incorporates five main production areas, namely, sintering, coke-chemical, blast-furnace, steelmaking, and rolling.

Sinter plant produces feedstock required for pig iron production: ca. 3 MMTA of sinter with a basic capacity of up to 1.8 and Fe content up to 56%.>

Coke-making production area provides primary fuel for pig iron production. Over 1.5 MMTA of coke is sintered from coal charge. After cooling and screening procedures, various types of product are obtained: coke, shot coke, and coke fines. Coal pitch, ammonium sulphate, and benzene are recovered from COG.>

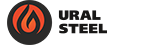

Blast-furnace shop produces over 2.5 MMTA of high-quality steelmaking and ordinary pig iron. Over 1.5 MMTA of marketable pig iron goes for export.>

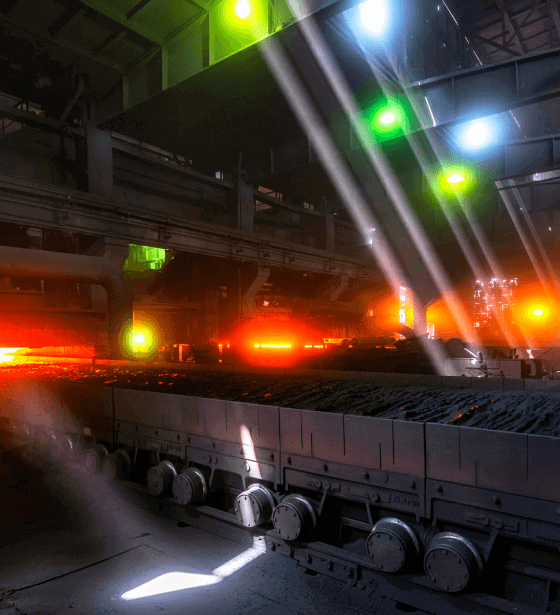

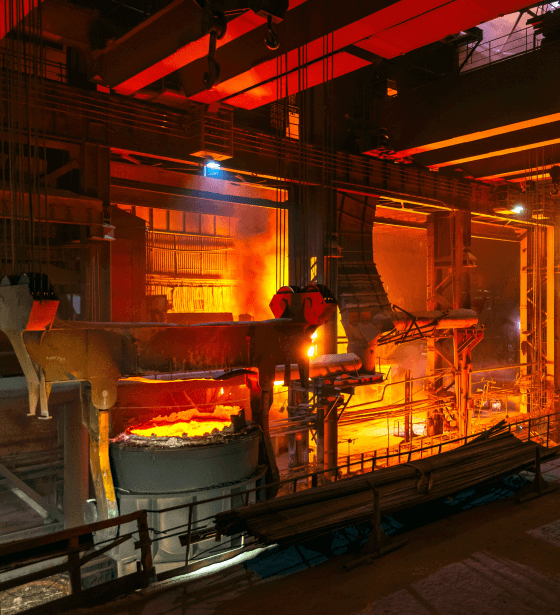

Electric Arc Furnace Melting Shop (EAF)is one of the most advanced plant facilities. Production capacity is around 100 refining steel grades with a total volume of around 1.5 MMTA. This is where round billets for railway wheel production and square billets for rail production are cast. The plant has successfully mastered FMF technology, which enables making steel by BOF smelting without using electricity.>

Slitting Lines Shop uses advanced equipment to make rolled products with excellent end-user performance from slabs received from the EAF. Mill 2800 rolls up to 1 MMTA of high quality steel for bridge construction, shipbuilding, large-diameter welded pipe production, structural steelwork.>

Shape Casting Shop has mastered the production of heavy castings for its own steelmaking and blast furnace operations, as well as for third-party mining and smelting companies. Workshop annual output exceeds 7,000 tonnes of heavy castings.>

Auxiliary units, integrated within the M&R Directorate and the Electrical Supervisor Service, ensure the stable operation of the main production areas.>

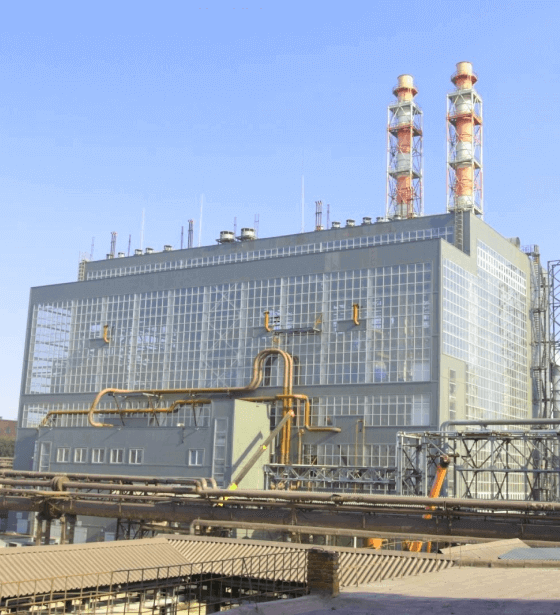

Plant’s own facilities guarantee its energy independence and promote efficient use of available fuel and energy resources. Ural Steel cogeneration plant produces electricity and heat for its own needs as well as provides heat to Novotroitsk.>